- Home

- Products

- About Us

- Contact Us

More Information

(+98) 912 833 4643

(+98) 912 833 4643

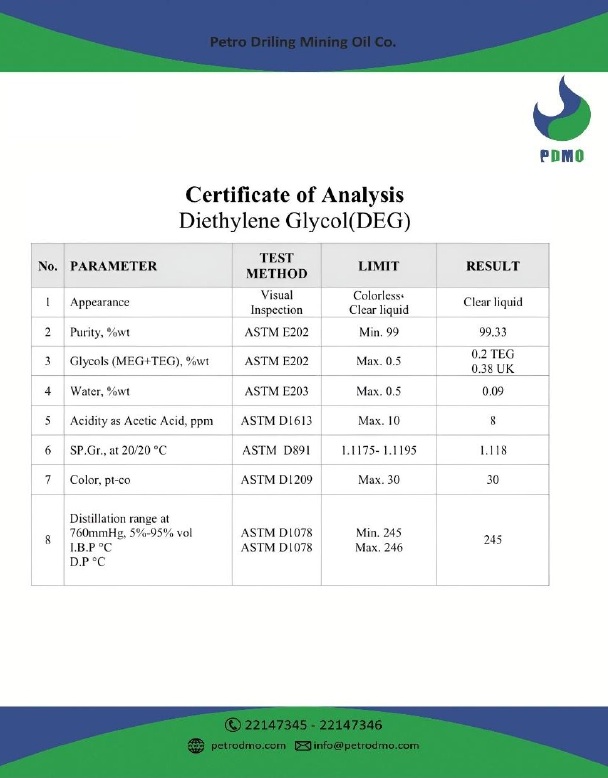

*DEG (Diethylene Glycol)* is a versatile chemical compound widely used in various industrial applications. It is a member of the glycol family and shares some properties with Monoethylene Glycol (MEG) and Triethylene Glycol (TEG).

*Properties of DEG:*

1. *Chemical Formula*: C₄H₁₀O₃

2. *Molecular Weight*: 106.12 g/mol

3. *Appearance*: Clear, colorless, and odorless liquid.

4. *Density*: 1.118 g/cm³ at 20°C.

5. *Boiling Point*: 245°C.

6. *Melting Point*: -10.5°C.

7. *Solubility*: Miscible with water, alcohols, and many organic solvents.

8. *Hygroscopic Nature*: Absorbs moisture from the air.

*Production Process of DEG:*

DEG is primarily produced as a byproduct during the production of Monoethylene Glycol (MEG). The process involves the following steps:

1. *Ethylene Oxide Production*:

– Ethylene (derived from petroleum or natural gas) is oxidized in the presence of a catalyst to produce ethylene oxide (EO).

2. *Hydration Reaction*:

– Ethylene oxide reacts with water to form MEG, DEG, and TEG. The reaction conditions (temperature, pressure, and catalyst) determine the ratio of these products.

3. *Separation and Purification*:

– The crude mixture of MEG, DEG, and TEG is separated through distillation. DEG is collected as a middle fraction.

4. *Final Product*:

– The purified DEG is stored in tanks and transported for industrial use.

*Applications of DEG:*

1. *Solvents*:

– DEG is used as a solvent in paints, inks, resins, and dyes due to its ability to dissolve a wide range of substances.

2. *Humectants*:

– DEG is used in personal care products like lotions, creams, and toothpaste to retain moisture.

3. *Plasticizers*:

– DEG is used as a plasticizer in the production of polyurethanes and other polymers.

4. *Gas Dehydration*:

– DEG is used in natural gas processing to remove water vapor from the gas stream.

5. *Antifreeze and Coolants*:

– DEG is used in some antifreeze formulations, although it is less common than MEG.

6. *Other Applications*:

– Used in the production of adhesives, paper, and textiles.

– Acts as a chemical intermediate in the synthesis of other compounds.

*Advantages of DEG:*

1. *Versatility*: Used in a wide range of industries.

2. *Efficiency*: Effective at low concentrations in applications like gas dehydration.

3. *Cost-Effective*: Relatively inexpensive compared to alternative chemicals.

*Disadvantages of DEG:*

1. *Toxicity*: Requires careful handling and storage.

2. *Environmental Concerns*: Improper disposal can harm ecosystems.

3. *Flammability*: Combustible at high temperatures.

Tehran, Saadat Abad, Keshavarz Boulevard, Sefid Tower

info@petrodmo.com

(+98) 990 312 4793

(+98) 991 108 8952

(+98) 912 833 4643

Copyright © 2025 PetroDMO