Project Description

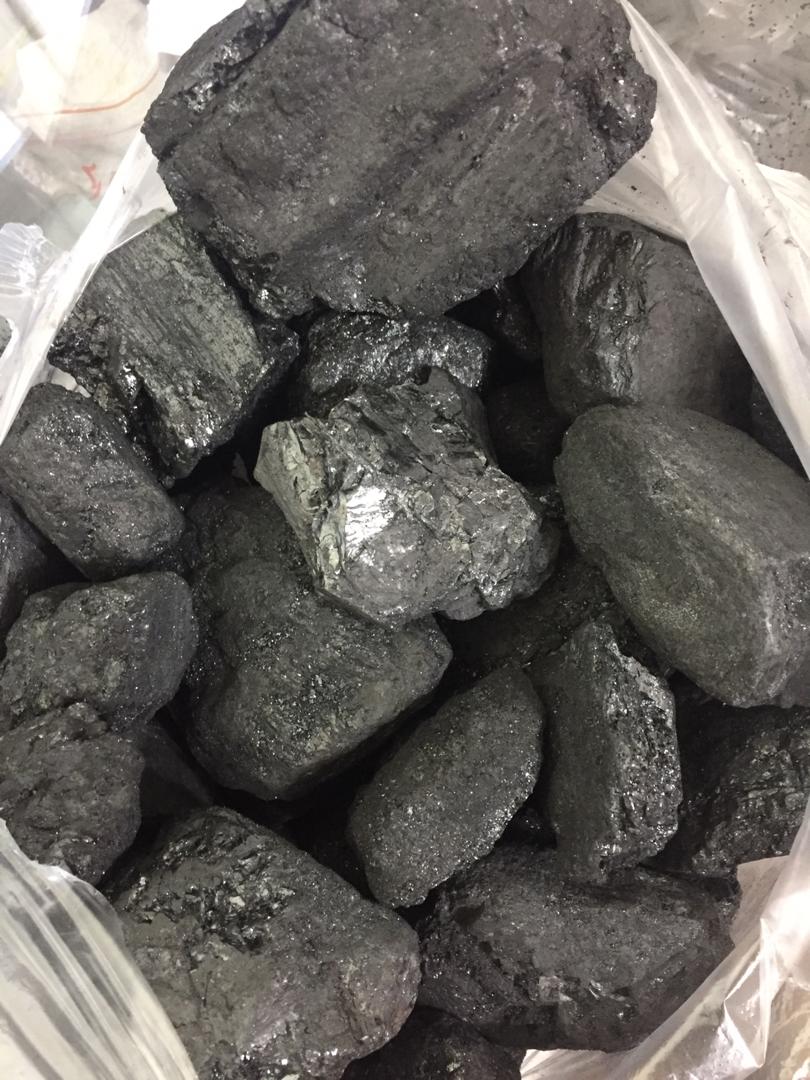

Anthracite Coal

Anthracite coal, mined from the planet’s oldest geological formations, has spent the longest time underground. The coal has been subjected to the most pressure and heat, making it the most compressed and hardest coal available. Hard coal contains greater potential to produce heat energy than softer, Click on the link to order the bulk caustic soda flake.

FEATURES

Common Uses

Anthracite also is the most brittle among coal types. When burned, it produces a very hot, blue flame. A shiny black rock, anthracite is used primarily for heating residential and commercial buildings in all over the world .

Characteristics

Anthracite contains a high amount of fixed carbon—80 to 95 percent—and very low sulfur and nitrogen—less than 1 percent each. Volatile matter is low at approximately 5 percent, with 10 to 20 percent ash possible. Moisture content is roughly 5 to 15 percent. The coal is slow-burning and difficult to ignite because of its high density, so few pulverized, coal-fired plants burn it.

-

Heating value:

- Anthracite burns the hottest among coal types (roughly 900 degrees or higher) and typically produces approximately 13,000 to 15,000 Btu per pound. Waste coal discarded during anthracite mining, called culm, contains approximately 2,500 to 5,000 Btu per pound.

-

Availability:

- Scarce. A tiny percent of all remaining coal resources are anthracite. Anthracite was mined heavily during the late 1800s and early 1900s, and remaining supplies became harder to access because of their deep location. The largest quantity of anthracite ever produced .

Anthracite is considered “nonclinkering” and free-burning because when it is ignited it does not “coke” or expand and fuse together. It is most often burned in underfeed stoker boilers or single-retort side-dump stoker boilers with stationary grates. Dry-bottom furnaces are used because of anthracite’s high ash fusion temperature. Lower boiler loads tend to keep heat lower, which in turn reduces nitrogen oxide emissions.

Particulate matter, or fine soot, from burning anthracite, can be reduced with proper furnace configurations and appropriate boiler load, underfire air practices, and fly ash reinjection. Fabric filters, electrostatic precipitators (ESP), and scrubbers can be used to reduce particulate matter pollution from anthracite-fired boilers. Anthracite that is pulverized before burning creates more particulate matter.

Inferior coal rejected from anthracite mines is called culm. This has less than half the heat value of mined anthracite and higher ash and moisture content. It is used most often in fluidized bed combustion (FBC) boilers.